The V-Cone® is a highly customizable flowmeter that measures flow based on the Bernoulli principle. Thanks to a flow detection design that calms vortices and turbulence, this flowmeter maximizes accuracy and minimizes line intrusion.

Its reduction ratio of 10:1 or more gives it great flexibility in a wide range of difficult flow applications with large flow ranges. Thanks to its self-conditioning technology, the V-Cone® requires little or no straight pipework upstream and downstream of the meter.

This makes it an ideal solution for retrofit projects or sites where space and weight are an issue. Offered in line sizes ranging from 0.5″ to 120″, it is suitable for a variety of applications in the oil & gas and industrial segments.

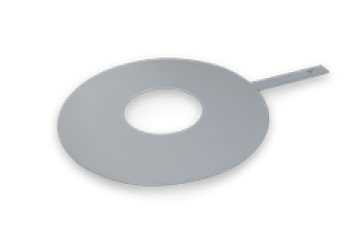

V-Cone® technology is offered in a range of products including Wafer-Cone®, which offers the technology in a flangeless, field-replaceable element, and VM V-Cone®, specially designed for municipal water applications.