Analysing chimney exhaust gases of ship

By facilitating compliance with stringent emission regulations, reducing harmful gas discharges, and promoting fuel efficiency, Fuji Electric's laser gas analyser contributes significantly to environmental protection, aligning maritime operations with sustainability goals and ecological preservation.

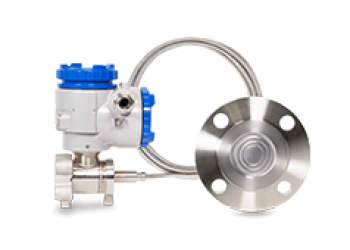

Fuji Electric's innovative ZQS laser gas analyzer ffor marine exhaust, designed for scrubber and EGCS (Exhaust Gas Cleaning Systems), represents a significant step forward in adherence to MARPOL Annex VI regulations on sulfur emissions, in line with International Maritime Organization(IMO) guidelines. By offering fast, accurate, and real-time analysis of exhaust gases, specifically SO2 and CO2, this technology enables ships to continuously monitor emissions with unparalleled precision.

The laser gas analyser's rapid response time, coupled with its capability to determine exhaust gas conditions after the scrubbing process, empowers optimized control over the SOx scrubber's pump operation. This, in turn, ensures compliance with sulfur emission limits while simultaneously enhancing fuel economy and reducing operational costs. Its compact design, a fraction of the size of conventional analysers, facilitates easy installation, both in retrofitting existing vessels and incorporating into new ships. Moreover, the system's stability, extended maintenance cycles, and resistance to dust accumulation guarantee consistent performance and low upkeep requirements.

For additional gas measurement, Fuji Electric'sanalyser infrared gas ZPA is specifically designed for marine applications. Robust and reliable, it enables precise measurement of gas concentrations such as NO, SO₂, CO₂, CO, CH₄ and O₂, essential for emissions control on board ships. Thanks to its advanced infrared technology, this device guarantees stable performance even under harsh environmental conditions, meeting the stringent requirements of the marine industry.