How to measure the mass and volume flow rate of liquid, water, gas or steam?

Our experts explain the definition, operation and principle, and present the different types of flowmeters, their installation and maintenance.

Learn all about flow measurement.

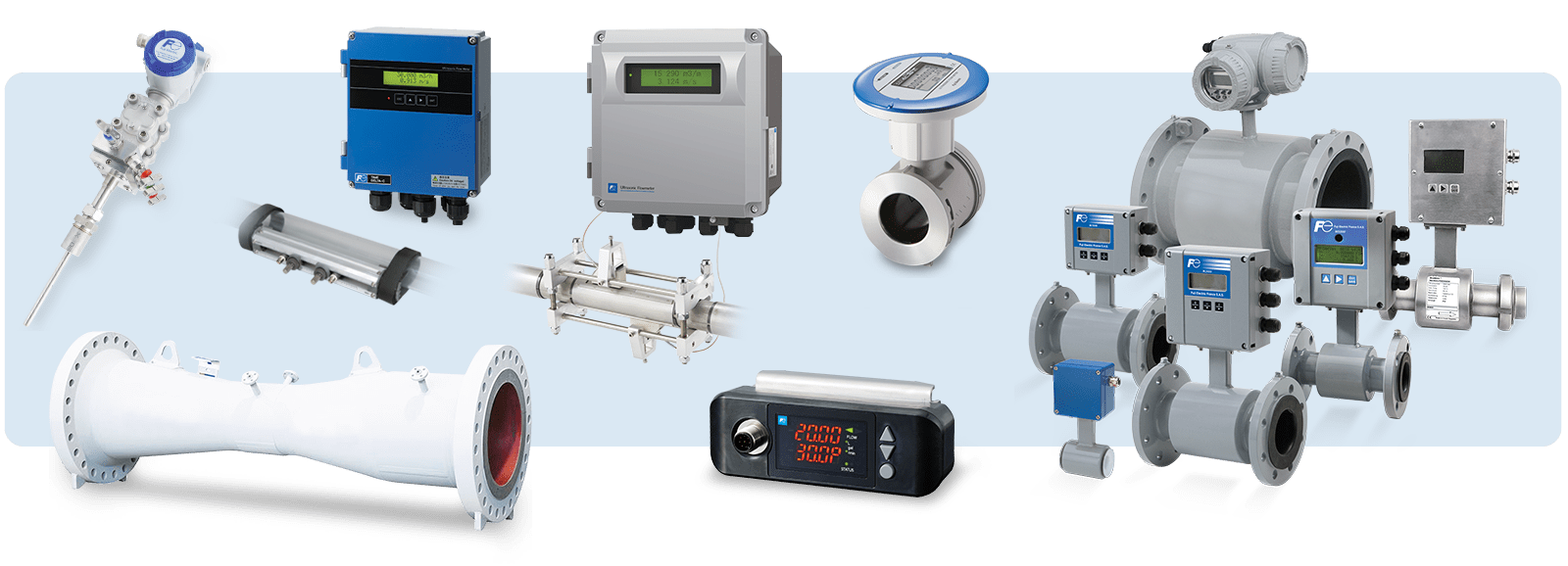

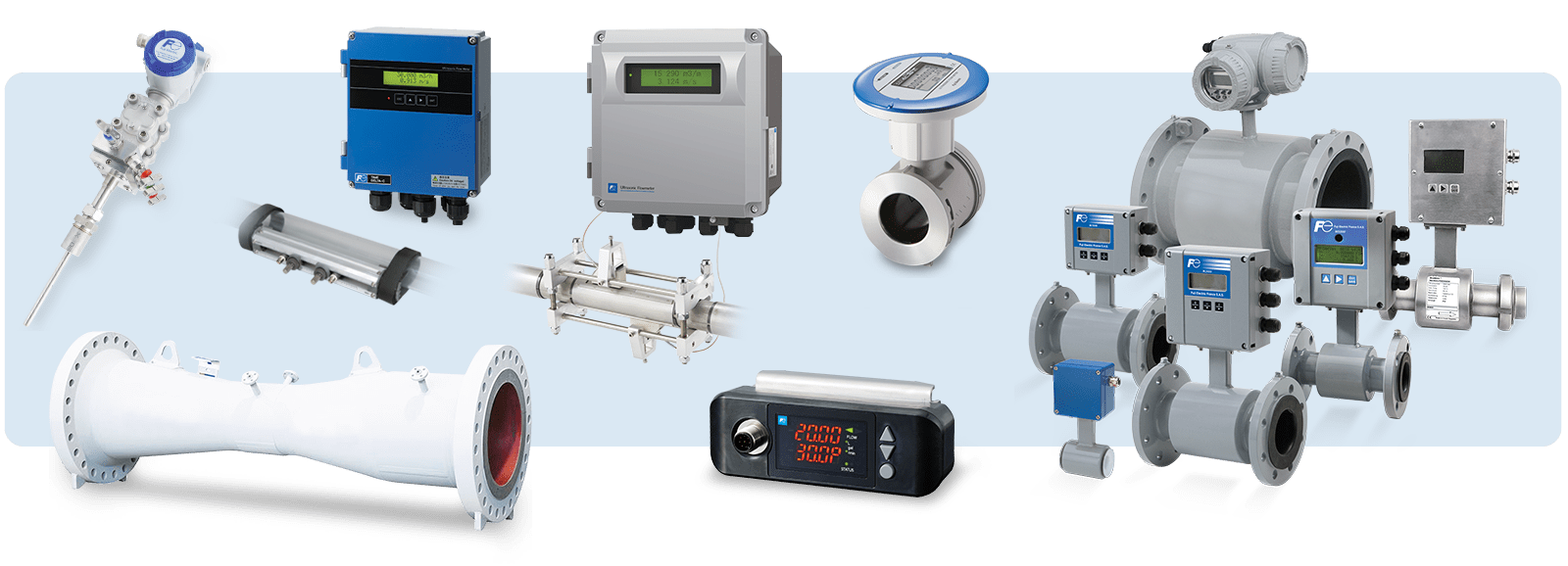

Flowmeters measure the flow of fluids through pipes and are used in most industrial processes. There are several categories of flowmeter.

In order to select the most suitable flowmeter type for a particular application, it is important to take into account process conditions, desired range and accuracy, fluid cleanliness requirements and whether it will be used to measure liquids or gases.

What is flow meter and what is the definition of flow rate?

A distinction is made between volume flowmeter and the mass flow meter. A volumetric flow meter is a versatile instrument that measures the quantity of fluid (volume) passing through a given point in a given time. This device measures the volume and flow rate of the fluid flowing through a pipe, generally a liquid flow rate like water flow rate a gas flow rate and a steam flow rate.

A distinction is made between volume flowmeter and the mass flow meter. A volumetric flow meter is a versatile instrument that measures the quantity of fluid (volume) passing through a given point in a given time. This device measures the volume and flow rate of the fluid flowing through a pipe, generally a liquid flow rate like water flow rate a gas flow rate and a steam flow rate.

Some measuring instruments measure mass flow, i.e. the mass of fluid flowing through a pipe over a given period of time. Conversion between volume flow and mass flow is possible when the density of the fluid is known, and other characteristics such as pressure and temperature are also known.

Note: Flow meters and flow indicators should not be confused, as flow indicators do not measure the value of flow, but simply indicate whether or not fluid is moving in a circuit.

What is the unit of flow measurement?

The volumetric flow rate for measuring the flow of liquids and gases, generally represented by the symbol Q, is normally expressed in m3/h or l/s.

The volumetric flow rate for measuring the flow of liquids and gases, generally represented by the symbol Q, is normally expressed in m3/h or l/s.

Mass flow is expressed in grams per second (g/s) or kilograms per hour (kg/h). A common mistake made when installing flowmeters is to confuse total counters with flow units.

Total flow sensors measure the flow that has passed through the meter since it was first switched on.

How to choose a flow meter?

Modern flowmeters are manufactured using a wide range of technologies, exploiting a variety of physical phenomena. Their research and selection require the verification of a number of parameters.

Modern flowmeters are manufactured using a wide range of technologies, exploiting a variety of physical phenomena. Their research and selection require the verification of a number of parameters.

Liquid flow meter and water flow sensor, gas flow meter (e.g. air) or steam flow meter are not the same, so you need to consider what will be flowing through the pipe. The choice depends of the flow meter application and types of fluid.

- Volume or mass flow meters

Flow transmitter is capable of measuring volumetric flows, but in some cases, you may wish to measure mass flows as well.

- Fluid operating conditions

What is the maximum pressure of the fluid flow to be measured?

What is the minimum and maximum temperature of the medium to be measured?

The ability of a flow rate meter to measure temperature depends on the type of flow sensor.

Some flow measurement devices are only suitable for measuring a single temperature, while others can measure a wide range of temperatures.

What are the minimum and maximum flow rates you will be measuring ?

Pipe size

Pipe size- Pressure losses

For a low flow rate, the pressure drop involved in installing a flow transmitter is a major cost factor.

Minimising pressure loss means minimising frictional losses in the pipework.

How to choose a flow meter accuracyOne of the main objectives in designing a flow sensor is to minimise frictional pressure drop as much as possible.

The pressure drop across a flow transmitter should be minimal and constant under different operating conditions.

- The outside environment

- Installation requirements:

Generally speaking, we also need to consider the installation conditions for future flowmeters.

Generally speaking, we also need to consider the installation conditions for future flowmeters.

In general, the installation conditions of future flow rate sensors should also be considered.

When a pipe network has bends, valves, diameter changes and other irregularities, disturbances in the fluid flow of the medium occur and some measurement technologies are sensitive to these disturbances.

In order to avoid measurement errors due to these disturbances, it is necessary to place enough straight pipe in front of the flow transmitter so that the fluid flow is not disturbed.

This straight length of pipe in front of flow measuring instruments is expressed in terms of the pipe diameter (DN).

Other factors to consider are the accuracy and repeatability of the flow rate meter, but also the analogue or pulse output signal and the communication protocol.

Other factors to consider are the accuracy and repeatability of the flow rate meter, but also the analogue or pulse output signal and the communication protocol.

- Accuracy must be stable, i.e. the variation in measurement error when the operating environment changes is within a fixed range.

- The flow meter must have high repeatability, i.e. the difference between two consecutive measurements must lie within a fixed range. This ensures that the meter can measure the same flow rate under different pressure conditions and with varying inlet flow rates.

- The output signal is available as 4-20mA, 0-10V, 4-20mA/0-10V, pulse, digital HART, MODBUS.

How does a flowmeter work and what is its principle?

Have you ever wondered how a flow sensor works? Let's discuss the different popular flow rate measurement technologies for measuring the flow of liquids, gas and steam.

What are the different flowmeter technologies?

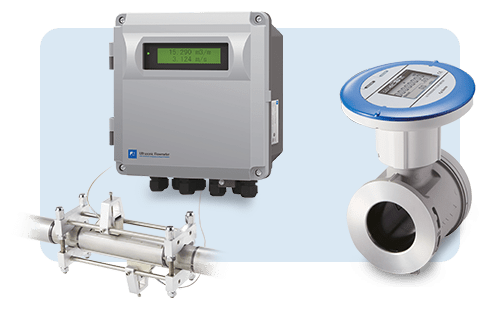

Visit electromagnetic flowmeters are composed of a transmitter and a sensor that measure the flow rate.

Visit electromagnetic flowmeters are composed of a transmitter and a sensor that measure the flow rate.

When a fluid passes through a pipe, the electromagnetic flowmeter's external sensor measures an induced voltage generated by the liquid. The transmitter measures the voltage produced by the sensor, transforming it into a flow rate value. An electromagnetic flowmeter measures flow using a pair of electrodes and a collection of coils. The electromagnetic flowmeter coils are driven by the transmitter as a result of applied currents. Once energized, a magnetic field forms between the two coils. When the pipe is filled and the fluid begins to flow, the force of the magnetic field separates the negatively and positively charged particles from the fluid.

Visit Faraday's Lawmathematically described by E = k*B*D*V, is a flow principle of magnetic flowmeters.

Visit Faraday's Lawmathematically described by E = k*B*D*V, is a flow principle of magnetic flowmeters.

The induced voltage (E) is directly proportional to the velocity (V) of the fluid flowing in the magnetic field (B).

The electrode circuit transmits the induced voltage to the transmitter, which transforms the velocity into a quantitative measurement.

The volume of the fluid is estimated from this known velocity and the surface area of the pipe.

Why choose an magnetic flow meter?

- Economical for liquids such as water, wastewater, aggressive chemicals and sludge

- Low maintenance (not sensitive to particles, no moving parts, no clogging)

- Wide range of flow meter applications (lining materials, electrode options, pipe diameters)

- Bidirectional flow measurement

- High measurement dynamics (measurement of very small and very large volume flows)

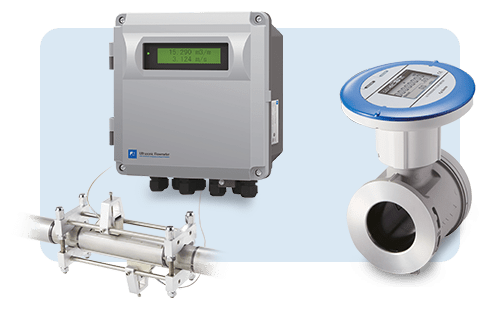

Ultrasonic flowmeters :

Ultrasonic flowmeters use the transit time difference or Doppler effect method. The transit time method is based on the fact that the transmission speed of an ultrasonic signal depends on the flow velocity of the medium. An ultrasonic wave moving with the flow moves faster than one moving against it. Two transducers are installed face to face on the outer wall of the pipe. The transducers each emit an ultrasonic pulse and detect the difference in pulse transit time to calculate the flow rate.

Why choose an ultrasonic flowmeter?

Visit non-intrusive clamp-on ultrasonic flowmeter technology offer numerous advantages and revolutionizes flow measurement throughout history :

Visit non-intrusive clamp-on ultrasonic flowmeter technology offer numerous advantages and revolutionizes flow measurement throughout history :

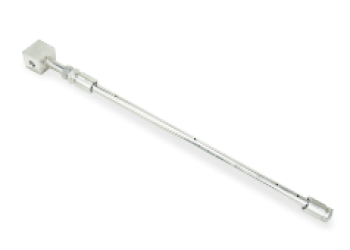

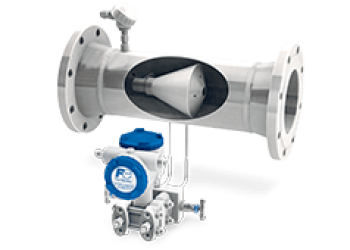

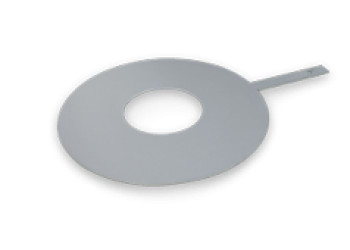

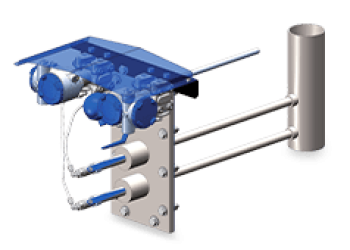

Differential pressure flow meters with primary element

Technology using pressure transmitter differential (DP) for DP flow measurement with primary element uses a variation of Bernoulli's principle to measure the volumetric flow of fluid in a pipe.

Technology using pressure transmitter differential (DP) for DP flow measurement with primary element uses a variation of Bernoulli's principle to measure the volumetric flow of fluid in a pipe.

In our Bernoulli's principleIt is stipulated that the flow velocity increases and the pressure decreases as the flow passes through a restriction in the pipe. This makes it possible to determine the differential pressure across the restriction. The square root of this differential pressure is proportional to the flow rate. A differential pressure (DP) flowmeter consists of two elements, a primary element which causes a pressure drop, and a secondary element (a pressure transmitter) to measure the differential pressure.

Why choose a differential pressure flow meter with a primary element?

- Simple device with no moving parts

- Economical

- Installation in any position

- Wide range of applications and processes (gases, liquids, steam)

How to install a flow meter ?

When installing flowmeters, remember to install the meter in a straight section of pipe to eliminate disturbances caused by elbows, valves and other obstructions.

How do I set up a flow meter?

If you want to set up a flow rate meter, you have to do the commissioning.

Commissioning a flowmeter

Installing the instruments and connecting the pipes is called commissioning.

It's a complex job that requires a team of skilled people with a wealth of experience.

This operation can be carried out by technicians trained in process instrumentation, or by the manufacturer's technical services.

Flow meter training

Instrument training for the user is very important in order to configure the flowmeter according to expectations.

This training ensures that you know how to read the flowmeter screen, and how to use the configuration menu and parameters.

You'll be able to ask any questions you may have.

How should a flow meter be maintained?

The importance of efficient, regular maintenance of flow rate sensors is that in normal operation, flow meters are exposed to a wide variety of contaminants.

The importance of efficient, regular maintenance of flow rate sensors is that in normal operation, flow meters are exposed to a wide variety of contaminants.

These can be in the form of suspended solids carried by the medium being measured (such as dirt in water) or liquid/solid deposits formed on the outer surface of the flow transmitter (such as scale or corrosive materials). To minimise the risk of fouling and to ensure accurate measurement over long periods of time, it is necessary to clean it regularly.

Ideally, a flow meter should be cleaned once a year, or more frequently if it is exposed to particularly harsh conditions.

Cleaning in-line flow rate meter not only extends their life, but also ensures optimum performance at all times.

Regular cleaning prevents dirt and other blockages from building up in your meters, eliminating false readings and ensuring that you get an accurate reading every time you use them.

Non-intrusive flowmeters have the advantage of not being in direct contact with the fluid and requiring no maintenance.

Calibration is important, as it ensures accurate readings. If a meter is not properly calibrated, it will not provide reliable data that can be used for plant maintenance and improvement. It is also important to calibrate meters before they are put into service, as poor calibration can lead to a drop in accuracy over time. Calibration ensures that measurements are taken at a constant point that delivers accurate results every time.

The best way to ensure the continued accuracy of your equipment is to use ongoing verification, maintenance and calibration services.

A well-maintained flow meter will operate more efficiently than one that is not, resulting in lower operating costs for your business.

How to test a flow meter and calibrate a flow meter?

A flow sensor needs to be regularly calibrated to ensure that it continues to provide accurate readings.

A flow sensor needs to be regularly calibrated to ensure that it continues to provide accurate readings.

Calibration is the process of checking that the meter is operating correctly and providing accurate readings.

Calibration should be carried out in accordance with the manufacturer's datasheet , usually on an annual basis.

Flow meter calibration involves comparing its output with a known input.

This can be achieved using an external reference by comparing the output with another device, such as a secondary flowmeter.Professional calibration of the device is usually carried out by the manufacturer or supplier of the flow measurement equipment. However, if the warranty period has expired, or if the manufacturer or supplier does not provide a calibration service, you can send your flowmeter to a specialist company for calibration.

Flow meter applications - What are the areas of application of flow meters?

The different categories of flowmeters are used for flow measurement and control in several applications, including paper and cardboard industry, mining and metalworking, clean water and wastewater, food processes, chemicals and petrochemicals, oil and gas.

The different categories of flowmeters are used for flow measurement and control in several applications, including paper and cardboard industry, mining and metalworking, clean water and wastewater, food processes, chemicals and petrochemicals, oil and gas.

They are suitable for a wide range of applications, from clean or contaminated liquids, through highly corrosive or abrasive gases, to saturated and superheated steam. The choice of technology depends on the application and the constraints of the industrial environment.

Fuji Electric France is at your disposal to help you find the right flowmeter for your application.

A distinction is made between volume flowmeter and the mass flow meter. A volumetric flow meter is a versatile instrument that measures the quantity of fluid (volume) passing through a given point in a given time. This device measures the volume and flow rate of the fluid flowing through a pipe, generally a

A distinction is made between volume flowmeter and the mass flow meter. A volumetric flow meter is a versatile instrument that measures the quantity of fluid (volume) passing through a given point in a given time. This device measures the volume and flow rate of the fluid flowing through a pipe, generally a  The volumetric flow rate for measuring the flow of liquids and gases, generally represented by the symbol Q, is normally expressed in m3/h or l/s.

The volumetric flow rate for measuring the flow of liquids and gases, generally represented by the symbol Q, is normally expressed in m3/h or l/s.

Modern flowmeters are manufactured using a wide range of technologies, exploiting a variety of physical phenomena. Their research and selection require the verification of a number of parameters.

Modern flowmeters are manufactured using a wide range of technologies, exploiting a variety of physical phenomena. Their research and selection require the verification of a number of parameters.

Pipe size

Pipe size Generally speaking, we also need to consider the installation conditions for future flowmeters.

Generally speaking, we also need to consider the installation conditions for future flowmeters. Visit electromagnetic flowmeters are composed of a transmitter and a sensor that measure the flow rate.

Visit electromagnetic flowmeters are composed of a transmitter and a sensor that measure the flow rate. Visit Faraday's Lawmathematically described by E = k*B*D*V, is a flow principle of magnetic flowmeters.

Visit Faraday's Lawmathematically described by E = k*B*D*V, is a flow principle of magnetic flowmeters.

Visit

Visit

Technology using

Technology using

The importance of

The importance of  A flow sensor needs to be regularly calibrated to ensure that it continues to provide accurate readings.

A flow sensor needs to be regularly calibrated to ensure that it continues to provide accurate readings.

The different categories of flowmeters are used for flow measurement and control in several applications, including

The different categories of flowmeters are used for flow measurement and control in several applications, including