Buying guide for hydrostatic level sensors

What is the principle of hydrostatics?

Hydrostatics is a science that deals with the properties of vacuum, liquid and vapor.

Hydrostatics is a science that deals with the properties of vacuum, liquid and vapor.

This discipline relies on the action of the pressure exerted by the fluid on its surface to determine the heights or volumes involved.

The principle of hydrostatics was developed in the 16th century by an Italian mathematician named Evangelista Torricelli (1608-1647). It is one of the fundamental principles of hydraulics.

What is a hydrostatic level sensor?

Hydrostatic level sensors measure hydrostatic pressure, which is proportional to the measured liquid level.

Hydrostatic level sensors measure hydrostatic pressure, which is proportional to the measured liquid level.

Consisting of a pressure-measuring cell, the sensor's stainless steel or other diaphragm reacts to changes in level.

The force exerted by the diaphragm is converted by the hydrostatic level sensor into an analog electrical output signal.

How is hydrostatic level measurement calculated?

The relationship between the height h of the liquid and the hydrostatic pressure P in a liquid at rest and at atmospheric pressure, can be written as follows:

- g = 9.81 m/s 2 , constant, the Earth's acceleration due to gravity (at sea level) ;

- ρ = density of the liquid ;

- h = height of liquid.

The pressure measured by the level pressure sensor is proportional to the liquid column. For example, for a water level measurement in a tank, the pressure varies by 100 mbar per meter of water column. For a tank height of 12 meters, the level sensor measures a pressure of 1.2 bar gauge to the sensor membrane.

How does hydrostatic level measurement work?

Hydrostatic level measurement involves determining the height of a liquid using the hydrostatic pressure exerted by the liquid on its surface.

Hydrostatic level measurement involves determining the height of a liquid using the hydrostatic pressure exerted by the liquid on its surface.

The higher the liquid level, the higher the measured pressure applied to the diaphragm. There are two different methods for measuring hydrostatic level.

Measurement methods: gauge pressure and differential pressure.

A gauge pressure transmitter measures the static pressure at a low position in the reservoir. This pressure is then converted to height using the hydrostatic level equation.

In closed vessels, a second measurement is required to measure the pressure of the gaseous atmosphere (air or gas above the liquid being measured). A differential pressure transmitter measures the differential pressure at two different points in the tank, where the tank is subjected to a pressure different from atmospheric pressure. The measuring cell calculates the pressure difference between these two points to determine the liquid level.

What are the applications of level measurement with hydrostatic pressure sensor?

For accurate hydrostatic level measurement, the specific weight of the product in the tank or reservoir and gravity must be taken into account.

For accurate hydrostatic level measurement, the specific weight of the product in the tank or reservoir and gravity must be taken into account.

Hydrostatic pressure transmitters is preferred for applications where the liquid density is constant.

Common industrial applications for level measurement using pressure transmitter hydrostatic are as follows:

Level control in tanks or pressure vessels

Level control in tanks or pressure vessels- Level measurement in open-air or ventilated industrial tanks

- Level-dependent pump start-up and shutdown in open water and wastewater pipes

- Dosing and distribution of liquids in processes

- Automation of industrial level control processes and data transmission. These pressure transmitters products are used in processes in the chemical and petrochemical industries (chemicals), the food industry (water, beverages, milk), the water industry (water and wastewater), the environment and theshipbuilding industry (seawater).

What are the advantages of hydrostatic level measurement?

Hydrostatic level probes use proven measurement technology and offer a number of advantages, including :

Hydrostatic level probes use proven measurement technology and offer a number of advantages, including :

- Reliable, precise measurement

- Insensitive to foam and viscosity

- Independent of liquid dielectric constant

- Easy to install

- Works even in the presence of agitators

- Compatible with all internal tank structures

- Wide measuring range

- Long-term stability

What are the disadvantages of hydrostatic level measurement?

- The hydrostatic level sensor only works on liquids.

- Hydrostatic level transmitters offer measurement by contact with the fluids to be measured.

- Level measurement is dependent on the density of the liquid to be measured and on the pressure in the vessel.

- Regular maintenance is required to clean the sensor membrane of deposits and debris. Hydrostatic level measurement solutions with flush diaphragms or hygienic connections avoid the creation of retention zones.

- Intervention on hydrostatic level transmitters may require draining the reservoir. Hydrostatic level measurement systems with integrated ball valves do away with this constraint. Level probes can be removed without emptying the tank.

How to choose a hydrostatic level sensor?

When choosing a hydrostatic pressure level sensor, it is important to know the following parameters:

- the nature of the liquid (water, milk, oil, chemicals, etc.)

- liquid density

- liquid corrosiveness and abrasiveness

- liquid height (measurement range)

- type of reservoir (atmospheric or pressurized)

- reservoir pressure

- fluid temperature

- type of process connection (flanged, screwed, hygienic, etc.)

- local or remote display

- IP rating

The choice of hydrostatic level sensor will depend on these parameters. The scale of the sensor's measuring cell, and the materials of construction such as Stainless Steel 316, Hastelloy C and Monel, all need to be adapted to ensure reliable, accurate measurement over time.

Fuji Electric solutions for liquid level measurement

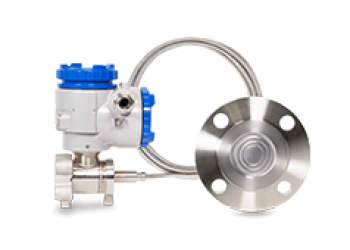

Fuji Electric manufacture state-of-the-art hydrostatic pressure transmitters that meet the specific needs of different industries. These field instruments include the diaphragm seal pressure transmitter and the hydrostatic level transmitter.

Fuji Electric manufacture state-of-the-art hydrostatic pressure transmitters that meet the specific needs of different industries. These field instruments include the diaphragm seal pressure transmitter and the hydrostatic level transmitter.

Fuji Electric's diaphragm seal pressure transmitter is designed for accurate pressure measurement in harsh and corrosive environments. This hydrostatic level sensor offer excellent long-term stability, high turndown ratio and accuracy, making it an ideal choice for demanding industrial applications.

Fuji Electric's pressure level sensor is specially designed for liquid level measurement. This sensor offers high precision, corrosion resistance and exceptional durability even under extreme conditions.

Fuji Electric's pressure level sensor is specially designed for liquid level measurement. This sensor offers high precision, corrosion resistance and exceptional durability even under extreme conditions.

These products offer benefits such as :

- Precise, reliable liquid level measurement

- Resistance to corrosive and harsh environments

- Long service life and low maintenance

Importance of hydrostatic level transmitter in industry

The hydrostatic level sensors are essential to ensure that theefficiency and safety of industrial processes that require precise liquid level measurement. The solutions offered by Fuji Electric, such as the diaphragm seal pressure transmitter the retractable level transmitter and the hydrostatic pressure level sensor are reliable, technologically advanced tools that can be used in a variety of industries to solve common problems associated with liquid level measurement.

The hydrostatic level sensors are essential to ensure that theefficiency and safety of industrial processes that require precise liquid level measurement. The solutions offered by Fuji Electric, such as the diaphragm seal pressure transmitter the retractable level transmitter and the hydrostatic pressure level sensor are reliable, technologically advanced tools that can be used in a variety of industries to solve common problems associated with liquid level measurement.

By choosing Fuji Electric as your trusted hydrostatic level transmitter supplier for these essential products, you benefit not only from high quality hydrostatic sensors, but also from a solid partnership and dedicated technical support to ensure the success of your projects.

Hydrostatics is a science that deals with the properties of vacuum, liquid and vapor.

Hydrostatics is a science that deals with the properties of vacuum, liquid and vapor. Hydrostatic level sensors measure hydrostatic pressure, which is proportional to the measured liquid level.

Hydrostatic level sensors measure hydrostatic pressure, which is proportional to the measured liquid level.

Hydrostatic level measurement involves determining the height of a liquid using the hydrostatic pressure exerted by the liquid on its surface.

Hydrostatic level measurement involves determining the height of a liquid using the hydrostatic pressure exerted by the liquid on its surface. LEVEL MEASUREMENT WITH GAUGE PRESSURE TRANSMITTER

LEVEL MEASUREMENT WITH GAUGE PRESSURE TRANSMITTER LEVEL MEASUREMENT WITH DIFFERENTIAL PRESSURE TRANSMITTER

LEVEL MEASUREMENT WITH DIFFERENTIAL PRESSURE TRANSMITTER For accurate hydrostatic level measurement, the specific weight of the product in the tank or reservoir and gravity must be taken into account.

For accurate hydrostatic level measurement, the specific weight of the product in the tank or reservoir and gravity must be taken into account. Level control in tanks or pressure vessels

Level control in tanks or pressure vessels

Fuji Electric manufacture state-of-the-art hydrostatic pressure transmitters that meet the specific needs of different industries. These field instruments include the diaphragm seal pressure transmitter and the hydrostatic level transmitter.

Fuji Electric manufacture state-of-the-art hydrostatic pressure transmitters that meet the specific needs of different industries. These field instruments include the diaphragm seal pressure transmitter and the hydrostatic level transmitter. Fuji Electric's pressure level sensor is specially designed for liquid level measurement. This sensor offers high precision, corrosion resistance and exceptional durability even under extreme conditions.

Fuji Electric's pressure level sensor is specially designed for liquid level measurement. This sensor offers high precision, corrosion resistance and exceptional durability even under extreme conditions. The hydrostatic level sensors are essential to ensure that theefficiency and safety of industrial processes that require precise liquid level measurement. The solutions offered by Fuji Electric, such as the

The hydrostatic level sensors are essential to ensure that theefficiency and safety of industrial processes that require precise liquid level measurement. The solutions offered by Fuji Electric, such as the