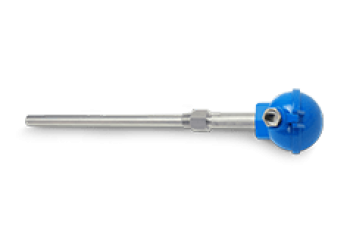

Temperature transmitter - FRC

ref : FRCFrom

567,00 € Request a quote

From

567,00 € Request a quote

From

191,00 € Request a quote

From

386,00 € Request a quote

From

285,00 € Request a quote

From

275,00 € Request a quote

From

65,00 € Request a quote

From

275,00 € Request a quote

Premium quality in every product

Local service near you

Customer support every step of the way

Seamless technical communication

Temperature measurement is an essential aspect of theautomation and industrial process control. Fuji Electric has developed a wide range of temperature probesof signal converters and conditioners and HART temperature transmitter indicators to meet the demands of your industrial applications.

Temperature measurement is an essential aspect of theautomation and industrial process control. Fuji Electric has developed a wide range of temperature probesof signal converters and conditioners and HART temperature transmitter indicators to meet the demands of your industrial applications.

Whether you're monitoring the temperature of a liquid, a gas or steam, or creating a product that requires temperature monitoring to guarantee its quality, several aspects are key:

There are a variety of technologies for measuring temperature, converting temperature and displaying results, each with its own advantages and disadvantages. Temperature sensors play a fundamental role in monitoring and controlling temperature controlof heating, reheating or cooling in industrial systems.

The most common types of temperature sensors include thermocouples (type K, J, etc.), RTD (Resistance Temperature Detector) sensors such as PT100 or PT1000, and thermistors (NTC).

PT100 and PT1000 RTD sensors

PT100 and PT1000 RTD sensors Resistance thermometers, also known as RTDs or resistance temperature detectors, are one of the most popular types of temperature sensor. They are used in a wide range of industries and applications, from the food industry to chemical plants. RTDs are made from materials with high electrical resistance, such as platinum, copper or nickel. RTD material resistance changes with temperature, so RTD resistance can be used to calculate temperature.

The most common type of RTD is the PT100, which has a resistance of 100 ohm at 0°C. The PT1000 has a resistance of 1000 ohm at 0°C. PT100 and PT1000 are available in a wide range of accuracy levels, from 0.5% to 0.01%.

They can be used for temperatures ranging from -200°C to +850°C, and are available in 2-wire, 3-wire or 4-wire versions.

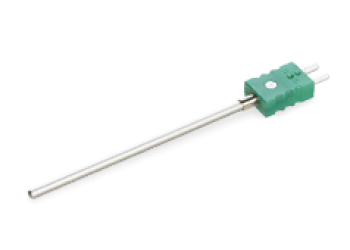

Thermocouple probes

Thermocouple probesA thermocouple consists of two wires of different metals, joined together at one end. The junction between the two wires is called the hot junction. The other end of the thermocouple wire is connected to a measuring device, such as a multimeter or temperature controller. When the hot junction is heated, a voltage is generated at the measuring device. This voltage is proportional to the temperature difference between the hot junction and the measuring device.

Thermocouple probes are available in a wide range of metals, such as copper-constantan, iron-constantan and chromel-alumel. Thermocouples are also available in a variety of accuracy levels, from 0.5% to 0.01%.

They can be used, as recommended, for temperatures up to 2300°C.

Signal converters

Signal convertersSignal converters and conditioners play an important role in the integration of PT100 resistance thermometers and thermocouple probes with PLCs or other digital devices. These devices transform the signal emitted by a temperature probe into a standard voltage or current signal, typically 4-20 mA or 0-10 V, compatible with industrial control and monitoring systems.

Signal converters are essential for industrial applications where accuracy, reliability and easy integration of temperature sensors are crucial.

HART temperature transmitter indicators

HART temperature transmitter indicatorsHART temperature transmitters are used in process automation applications to measure, convert and transmit temperature signals from resistance thermometers or thermocouples to PLCs or other digital devices. The transmitter converts the temperature probe signal into a standard voltage or current signal. The transmitter also features a display showing the temperature reading. It also features a HART communication interface, enabling the transmitter to be configured and calibrated using a HART pocket.

When choosing a temperature sensor, several factors need to be taken into account:

A temperature sensor works by converting a temperature measurement into an electrical signal that can be easily interpreted by a display device, temperature recorder or temperature controller. The most common types of temperature sensor include thethermocouples, RTDs (thermometric resistors), and thermistors. Each type uses a different physical principle to measure temperature. For example, a thermocouple generates a voltage that varies according to the temperature difference between its two ends, while an RTD changes its electrical resistance as the temperature changes.

A temperature sensor works by converting a temperature measurement into an electrical signal that can be easily interpreted by a display device, temperature recorder or temperature controller. The most common types of temperature sensor include thethermocouples, RTDs (thermometric resistors), and thermistors. Each type uses a different physical principle to measure temperature. For example, a thermocouple generates a voltage that varies according to the temperature difference between its two ends, while an RTD changes its electrical resistance as the temperature changes.

The main role of a temperature sensor is to provide accurate and reliable temperature measurement in a given environment. This information is vital in many sectors, such as industry, medicine and scientific research, where precise temperature control and regulation are essential. The temperature sensor is usually connected to a PLC or a industrial digital display. For example, in industrial processes, temperature must be strictly regulated to ensure product quality. In medicine, temperature probes are used to monitor patient health.

The main role of a temperature sensor is to provide accurate and reliable temperature measurement in a given environment. This information is vital in many sectors, such as industry, medicine and scientific research, where precise temperature control and regulation are essential. The temperature sensor is usually connected to a PLC or a industrial digital display. For example, in industrial processes, temperature must be strictly regulated to ensure product quality. In medicine, temperature probes are used to monitor patient health.

There are several types of temperature probes, each with its own specific characteristics and applications:

There are several types of temperature probes, each with its own specific characteristics and applications:

Each of these probe types has advantages and disadvantages that make them more or less suitable for use in your application or system.

Visit temperature probes are essential for industrial companies to ensure accurate and reliable measurements.

Visit temperature probes are essential for industrial companies to ensure accurate and reliable measurements.

For example, in the cement industry, they monitor high temperatures in rotary kilns and grinding mills to maintain product quality and prevent overheating. In the chemical sector, they monitor thermal reactions to optimize process efficiency and safety. Renewable energies also benefit from these probes, which ensure that components in solar and wind power plants function correctly, thus extending the life of the equipment.

Thermal power plants use sensors to manage boiler and turbine heat, ensuring efficient energy conversion. For hydrogen applications, they monitor production and storage processes for safe operations. Incinerators rely on these instruments to control waste combustion, minimizing harmful emissions. In the marine sector, sensors ensure the smooth operation of propulsion systems and generators.

In metallurgy, they monitor melting furnaces and heat treatments to guarantee metal quality. Nuclear power plants use these probes to monitor reactors and cooling circuits, ensuring the safety of energy production.

The paper and cardboard industry uses temperature sensor technology to supervise drying and cooking processes, ensuring consistent quality of finished products. The oil and gas sector uses these devices to monitor drilling, refining and transportation, ensuring safe operations. Finally, industrial utilities, such as heating, ventilation and air conditioning (HVAC) systems, exploit these sensors to optimize energy consumption and maintain safe, comfortable working conditions.

Visit temperature probes are essential tools for the temperature control and regulation in industrial environments.

Visit temperature probes are essential tools for the temperature control and regulation in industrial environments.

Fuji Electric offers a complete range of solutions adapted to your specific needs, guaranteeing precision, reliability and compliance with safety and construction standards.

Whether you need to measure, convert or display temperature, we have the equipment and know-how to optimize your industrial processes.

By integrating state-of-the-art technologies and ensuring proper installation and maintenance, you can guarantee optimum results and maintain your industrial operations at high performance levels.

Our related articles

Find out how to calibrate a temperature sensor to guarantee accurate measurements. Follow our step-by-step guide to optimize your calibrations!

October 16, 2024

Find out how to master temperature units and conversions to boost your industrial performance.

October 16, 2024