In many industrial processes, air flow plays a critical role in product quality, waste reduction and overall efficiency. Accurately measuring air flow is for optimizing these processes and improving product quality while minimizing environmental impact.

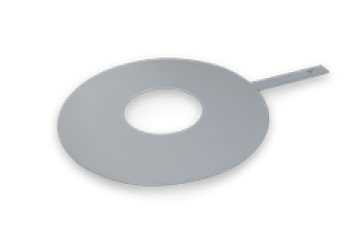

This is where the Fuji electric air flow metering system comes in. The system is designed to provide accurate and reliable measurements of air flow, helping industries to improve product quality, reduce waste, increase efficiency, and save costs. With the ability to accurately measure air flow, industries can optimize their processes, reduce variability and ensure that they are using the optimal amount of resources for each task.

By doing so, they can achieve significant cost savings, while also reducing their environmental impact. In this way, the Fuji electric air flow metering system can help to drive improvements in industrial processes, while also supporting the broader goal of sustainability.